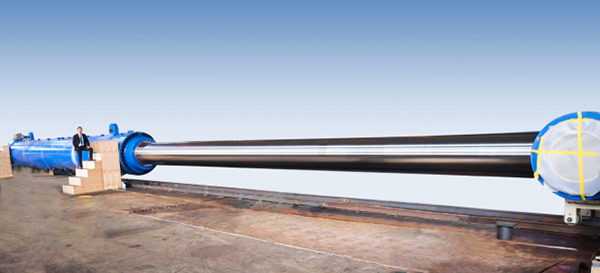

On March 31, 2022, the "Shuixinqi 1" piling platform owned by Zhejiang Shuixin was officially delivered. The total length of the pile-driving equipment is 118.50m, the width is 37.7m, the depth is 7.7m. The pile frame height is 137m from the designed waterline, and the towing height of the pile frame after the collapse is less than 48m from the design waterline. It satisfies the navigation requirements for river-spanning bridge, cross-sea bridge, and power passages.

All the movements of the pile frame are designed and manufactured by Jiangsu Hengli Hydraulic Co., Ltd. and are currently controlled by the luffing cylinder with the maximum thrust on the piling platform. The operation is convenient and safe the piling positioning adopts a centimeter-level satellite positioning system to ensure accurate positioning during piling, and the operation is not limited by the distance from the construction site.

Hengli customized the pile frame luffing hydraulic cylinder and system for the "Shuixinqi 1" project. During the delivery period, we assisted the customer to complete the on-site installation, and successfully carried out the 90-degree boom pitch test, which contributed to the smooth delivery of the piling platform. Hengli was highly recognized by the customer.

The cylinder diameter of the pile frame luffing hydraulic cylinder is 1400mm, the rod diameter is 900mm, the stroke is 15500mm, and the shortest installation distance is 19800mm. The large size and excellent technology have achieved new achievements in Hengli's piling platform business segment, and have also enhanced the company's marketing position in offshore engineering and extra-large hydraulic cylinders.The hydraulic cylinder, which is professionally designed and made of high-quality materials, can withstand the maximum working pulling force of 19400kN and a maximum working thrust of 29700kN, and meets the working environment conditions required by third-party inspection organization for equipment used in marine engineering equipment, which helps the pile-driving equipment to complete all the movements of piling frame: forward, backward, hinge changing, and reverse frame efficiently and safely.

In order to perfectly complete this challenging large-scale project, we quickly set up a special design team was agreed in December 2020.

The design, technology, production, quality, thermal spraying and other departments were committed to make collaborated efforts, and eventually a detailed plan was specified on large parts machining process, geometric tolerance control, lifting and assembly method, and thermal spraying of oversized piston rod to ensure the smooth progress of production and manufacture, it has been unanimously approved by the client and design institutes while meeting various design indicators.

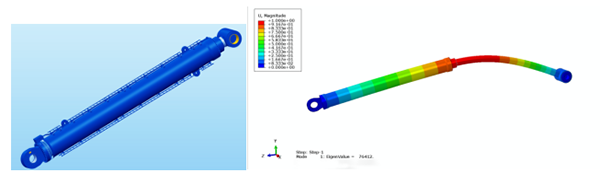

We have considered the load carrying capacity according to the working condition of pile frame forward and backward respectively. The design adopts FEM (Finite Element Method) to perform force analysis and dynamic performance simulation of individual components of an oversized hydraulic cylinder. Further improve the stability of the hydraulic cylinders by optimizing the structural design.

We also adopt the laser cladding process for the piston rod, which has high corrosion resistance and bonding strength between the coating and the piston rod body, making the coating difficult to peel off, according to the wet and high salt spray corrosion environment where the hydraulic cylinder is located.It is also serviceable and has low maintenance costs, further ensuring the service life of the hydraulic cylinders.

In addition, for this project, we also provided our customer with a luffing hydraulic system that allows for continuously speed throughout theentire hydraulic system, as well as fine-tune speed to ensure the safe, stable, and reliable operation of the luffing hydraulic cylinder.

In a general orientation, we work together to overcome the difficultiesfor technology, and we are always attentive to the smallest details to satisfy our customers, and ultimately help the piling platform business. This further shows Hengli’s strong ability to support large hydraulic cylinders for the marine engineering.In the future, Hengli will go hand in hand with customers to jointly promote Chinese marine engineering to a more brilliant future!

Directional Valve

Directional Valve  Pressure Valve

Pressure Valve  Flow Valve

Flow Valve  Proportional/Servo Valve

Proportional/Servo Valve  Cartridge Valve

Cartridge Valve  Other

Other  Solenoid On/Off Controls

Solenoid On/Off Controls  Electro-Proportional Valves

Electro-Proportional Valves  Pressure Controls

Pressure Controls  Directional Controls

Directional Controls  Flow Controls

Flow Controls  Logic Valves

Logic Valves